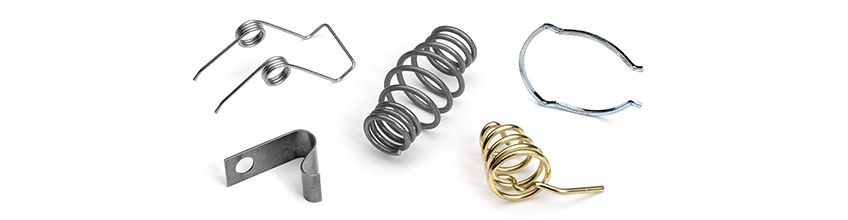

Custom Springs

Lee Spring offers a wide selection of custom spring capabilities, design and engineering support, extensive material options, and finish choices. For more than 100 years, we have provided extensive custom spring knowledge and experience to thousands of customers around the globe. Our experience combined with our custom spring manufacturing capabilities has made us a market leader in the design and manufacturing of custom springs.

Custom Spring Design and Engineering Support

Lee Spring understands the value of well qualified engineering support when designing custom springs. Our engineers provide assistance every step of the way from, design conception through project completion, our customer design team has all the necessary resources your project needs. Contact us for expert engineers for technical support custom spring project.

Global Custom Spring Manufacturing

Lee Spring’s expanding global presence and knowledge of the worldwide marketplace puts Lee Spring at the leading edge of creating market specific solutions for customers’ needs. Simply request a quote today or contact a Lee Spring location globally for design assistance or to answer any questions to help start your custom spring project.

Regulatory Compliance

Lee Spring is ISO 2015:9001 certified, REACH and RoHS compliant and ITAR Registered. Learn more about Lee Spring Regulatory Compliance.

Lee Spring India Pvt. Ltd. offers support for every stage of custom design, manufacturing and distribution:

- Application/Concurrent Engineering staff

- Regulatory expertise including RoHS, REACH and DFARS

- Proof of concept methodologies

- CAD assisted product design, drawing and modeling

- In-house prototype production services

- Factories outfitted to effectively accommodate both short and long production runs

- In-house tooling production including EDM

- Extensive experience working with Aerospace/Military Specifications (AS9100), Automotive Specifications (TS16949) and FDA Trial Support (21 CFR Part 820)

- Proprietary integrated quality control system

- State of the art computerized spring testing equipment

- Global supply chain network for both production and distribution

- Blanket agreement and consignment inventory management capabilities

- Pull/Kanban capabilities

- Ongoing Customer/Supplier improvement initiatives

- ISO 9001 Registered Quality Management System

From Start to Finish, Lee Spring Has the Custom Capabilities You Need!

Compression Springs

-

Outside Diameter: 0.025” – 5.75"/0.64mm – 146.1 mm

- Wire Diameter: 0.004" – 0.625"/0.10 mm – 15.88 mm

Extension Springs

- Outside Diameter: 0.025 – 5.75"/0.64 – 146.1 mm

- Wire Diameter: 0.005" – 0.625"/0.13 mm – 15.88 mm

Torsion Springs

- Outside Diameter: 0.025 – 5.75"/0.64 – 146.1 mm

- Wire Diameter: 0.005" – 0.187"/ 0.13 mm – 4.75 mm

Wave Springs

- Outside Diameter: 0.200" – 5.000"/5.08 mm –127 mm

- Inside Diameter: 0.150" – 4.54"/3.81 mm – 115.32 mm

Constant Force Springs

- Min. outside Diameter: 0.340"/8.636 mm

- Inside Diameter: 0.280" – 1.97"/7.11 mm – 50.04mm

- Min Length: 11.80"/299.72 mm

Distinct Production Capabilities

- Plastic Compression Springs

- Drawbar Springs

- Cone Springs

- Double Torsion Springs

- Extension Springs with Swivel Hooks

Wire Forms

- Wire Diameters: 0.010" – 0.240"/0.25 mm – 6 mm

- Maximum Finished Length: 60"/1524 mm

- Stampings: Strip Width: up to 3"/76.20 mm

- Strip Thickness: 0.005 to 0.062"/0.13mm – 1.57 mm

Fourslide Parts

- Strip Width: 0.010" – 0.500"/0.25 mm – 12.70 mm

- Strip Thickness: 0.003" – 0.125"/ 0.08 mm – 3.18 mm

- Wire Diameter: 0.005" – 0.187"/0.13 mm – 4.75 mm

Secondary Operations and Finishing

- Assembly

- Color Coding

- Electropolishing

- Grinding

- Heat Treating

- Looping

- Passivation

- Powder Coating

- Shot Peening

- Spring Setting

- Plating: Nickel, Zinc, Cadmium

- Special Finishes (e.g., Black Oxide)

Materials

- Beryllium Copper

- Beryllium Copper, Silver Coated

- Carbon Steel, Hard Drawn

- Carbon Steel, Oil Tempered

- Chrome Silicon, Oil Tempered

- Chrome Vanadium, Oil Tempered

- Elgiloy®*

- Hastelloy®** Inconel®† 600, 718 & x750

- Music Wire

- Phosphor Bronze

- Plastic Composites

- Stainless Steel, 300 Series

- Stainless Steel, 17-7

Please inquire regarding other materials.

*Elgiloy is a trademark of Elgiloy Ltd. Partnership.

**Hastelloy is a registered trademark of Haynes International Inc.

† Inconel is registered trademark of Special Metals Corporation

.png)